Máquina de serigrafía UV automática para botellas de plástico, 1-8 colores, 85 piezas/min

Datos del producto:

| Lugar de origen: | Dongguan China |

| Nombre de la marca: | SENNY |

| Certificación: | CE SGS |

| Número de modelo: | SL1688 |

Pago y Envío Términos:

| Cantidad de orden mínima: | 1 por ciento |

|---|---|

| Precio: | negotiable |

| Detalles de empaquetado: | Paquete de madera contrachapada |

| Tiempo de entrega: | 45 días |

| Condiciones de pago: | T/T |

| Capacidad de la fuente: | 10 pcs/mes |

|

Información detallada |

|||

| Grado automático: | Totalmente automático | Color impreso: | 1-8 colores |

|---|---|---|---|

| Servicios para después de la venta: | Video o en línea | Tiempo de entrega: | 45 días |

| Resaltar: | impresora de serigrafía automática para botellas de plástico,Máquina de serigrafía UV para botellas,impresora de serigrafía para botellas a 85 piezas/min |

||

Descripción de producto

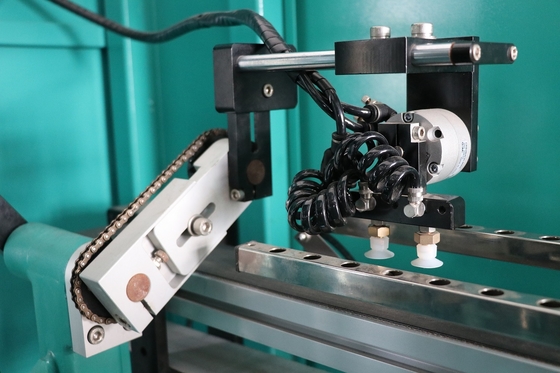

1-8 colores 85pcs/min Botella de plástico automática UV máquina de impresión de pantalla

Modelo de la máquina

- Más de 1.000 unidades de nuestras máquinas están en uso en todo el mundo.

- Hay una variedad de modelos disponibles para satisfacer las necesidades de los diferentes usuarios.

- Nuestras máquinas funcionan de manera estable, tienen cambios rápidos y son fáciles de usar.

- Las máquinas utilizan componentes eléctricos de marcas conocidas, lo que garantiza un rendimiento fiable.

Configuración opcional

- Tratamiento de la superficie con plasma(configuración estándar: tratamiento de superficie con llama): admite el tratamiento de superficie con plasma, lo que permite una modificación de material de alta precisión y bajo daño para mejorar la adhesión en procesos posteriores.Mientras tanto, el tratamiento de superficie con llama se ofrece como opción estándar, que se ajusta perfectamente a las necesidades de rentabilidad de los escenarios de tratamiento de superficie convencionales.

- Curado por LED-UV(configuración estándar: curado por lámpara UV): está equipado con tecnología avanzada de curado LED-UV, con arranque instantáneo y bajo consumo de energía.También está disponible la solución estándar de curado de lámparas UV., satisfaciendo eficazmente los diferentes requisitos de eficiencia de producción y presupuesto.

- Máquina de clasificación de botellas:Este equipo automatizado clasifica las botellas por especificación, material, color o información de la etiqueta a través de sensores de alta precisión.lo que lo hace adecuado para líneas de producción embotelladas.

- Máquina de inspección de calidad:Como dispositivo inteligente, integra funciones de reconocimiento visual y detección de defectos para llevar a cabo la inspección de productos en línea en tiempo real.Puede almacenar automáticamente los datos de inspección y generar informes, contribuyendo a reducir las tasas de defectos de los productos.

- ¿ Qué?Parámetros técnicos

| Modelo de la máquina | El número de personas a las que se refiere el apartado 1 del presente artículo |

| Velocidad máxima | 85 piezas/min |

| Diámetro redondo de la botella | 20 a 100 mm |

| Radius del frasco oval | 25 a 250 mm |

| Ancho de la botella ovalado | 20 a 120 mm |

| Altura de la botella | 50 a 300 mm |

| Área de impresión | El valor de las emisiones de gases de efecto invernadero es el valor de las emisiones de gases de efecto invernadero. |

Imprimir su visión

![]()

Sobre nosotros:

Senny sirve a diversas industrias, incluyendo alimentos, medicamentos, juguetes, cosméticos, productos químicos diarios, electrónica y productos decorativos.Aprovechando una serie de tecnologías de impresión automática, como la serigrafía, impresión en bloques, estampación en caliente, etiquetado, impresión offset e impresión digital

Desde 1994, Senny se ha adherido constantemente a la filosofía empresarial de proporcionar a los clientes productos y servicios de primera calidad.Utiliza componentes y materiales de control eléctrico de primer nivel para I + D y fabricación, mejorando continuamente la calidad de impresión de diferentes productos para satisfacer la creciente demanda del mercado de envases de alta calidad.

![]()

![]()