3 Estación de trabajo botellas máquina de impresión de pantalla para frascos tapas de varias formas 45pcs/min

Datos del producto:

| Lugar de origen: | PORCELANA |

| Nombre de la marca: | SENNY |

| Certificación: | CE SGS |

| Número de modelo: | Se aplicará el procedimiento siguiente: |

Pago y Envío Términos:

| Cantidad de orden mínima: | 1 por ciento |

|---|---|

| Precio: | negotiable |

| Detalles de empaquetado: | Paquete de madera contrachapada |

| Tiempo de entrega: | un mes |

| Condiciones de pago: | T/T o L/C |

| Capacidad de la fuente: | 15 PCS por año |

|

Información detallada |

|||

| Números del color: | 1-6 colores | Sistema de control: | El motor de las máquinas es el motor de las máquinas. |

|---|---|---|---|

| Grado automático: | Automático | Condición: | NUEVO |

| Velocidad de impresión: | 45-70pcs/min | Garantía: | 1 año |

| Servicio postventa: | Video o en línea | Condiciones de pago: | T/T |

| Detalles del paquete: | Paquete de madera contrachapada | Certificación: | CE |

| Resaltar: | Máquina de impresión en pantalla para 3 puestos de trabajo,máquinas de serigrafía para tapas de frascos,Máquina de serigrafía multicolor 45pcs/min |

||

Descripción de producto

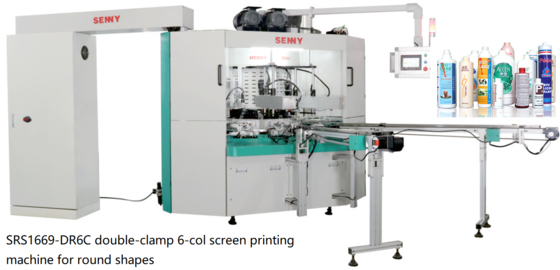

Máquina de serigrafía de 3 estaciones de trabajo para botellas, tapas y frascos de diversas formas, 45 piezas/min

Características de la máquina

Esta serigrafía totalmente automática, impulsada por un sistema de servomotor CNC, ofrece una versatilidad excepcional para aplicaciones de impresión de 360 grados. Maneja sin problemas varios tipos de envases, incluyendo botellas de plástico, vidrio y metal, frascos y tapas, adaptándose a diversas formas como diseños redondos, ovalados, triangulares, cuadrados y pentagonales, mientras utiliza múltiples colores de tintas UV para obtener resultados vibrantes y duraderos.

El innovador diseño de una sola fijación agiliza la producción al rotar los envases a través de estaciones de trabajo sucesivas, integrando la alimentación, el registro preciso, la preparación de la superficie, la impresión multicolor, el curado UV y la descarga en un proceso continuo y eficiente. Este enfoque integrado garantiza una precisión de impresión superior, mantiene una distancia mínima entre los patrones impresos y los fondos de las botellas, e incorpora un manejo suave para evitar daños en la superficie del producto.

Para la eficiencia energética, el sistema de curado UV puede estar parcial o totalmente equipado con tecnología LED-UV, lo que reduce significativamente el consumo de energía sin comprometer la calidad del curado.

Es posible cancelar una estación de serigrafía y curado UV, instalar un sistema de estampado en caliente y realizar la finalización simultánea de las funciones de serigrafía y estampado en caliente.

Se puede cancelar la última estación de serigrafía y curado UV, se puede instalar un sistema de inspección visual para los productos terminados y se pueden separar los productos calificados y no calificados después de la descarga.

La máquina está equipada con una función de gestión remota, que puede conocer o resolver de forma remota fallos de la máquina y problemas técnicos para los clientes, siempre que la red esté conectada en cualquier lugar.

Parámetros

| Modelo | SRS829-D | SRS1033-D | SRS1249-D | SRS1669-D | SRS829-DR | SRS1039-DR | SRS1249-DR | SRS1669-DR |

| Estaciones de impresión | 2 | 3 | 4 | 6 | 2 | 3 | 4 | 6 |

| Diámetro del producto | Formas complejas (20-100 mm) | Cilíndrico (20-100 mm) | ||||||

| Velocidad de impresión | Hasta 45 piezas/min | |||||||

| Área máxima de impresión | L250 mm X W160 mm | |||||||

| Altura del producto | 250 mm | |||||||

| Presión de aire | 6-7 bar | |||||||

| Potencia | 380v 50/60HZ | |||||||

![]()

Aplicaciones

La máquina de serigrafía UV SRS1669-DR es una máquina de serigrafía de plano de curado UV. El alcance de impresión es específico y se puede utilizar para la serigrafía de varios cuerpos planos cilíndricos o irregulares, como botellas de plástico, recipientes de plástico y otros envases similares que requieren efectos de curado UV.

Muestra de impresión

![]()

![]()

Contacto:

| SENNY PRINTING EQUIPMENT CO., LTD. | |

| Persona de contacto: | Siena Shen |

| Teléfono móvil/WeChat/Whatsapp: | +86 13650136019 |

| Correo electrónico: | siena.shen@senny.com.cn |